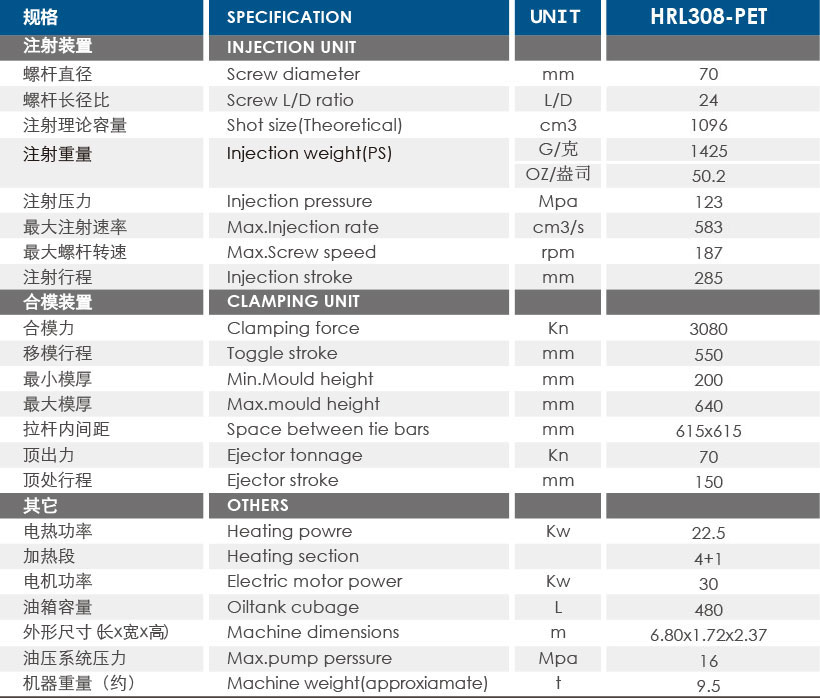

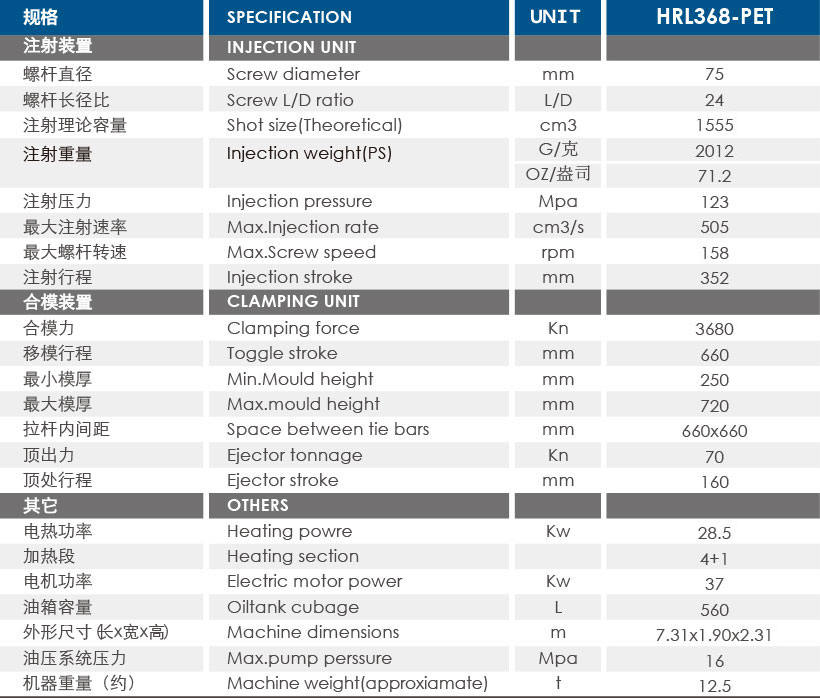

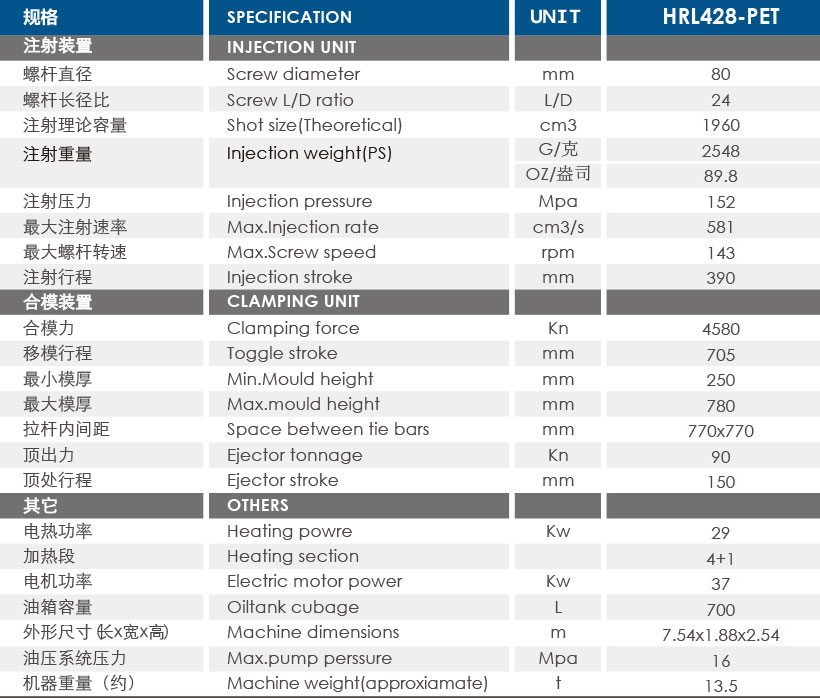

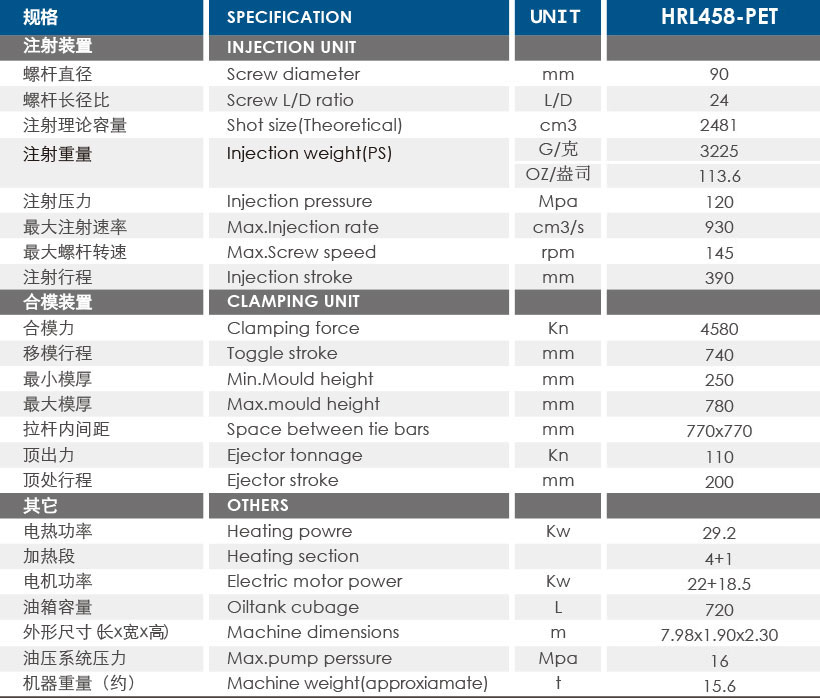

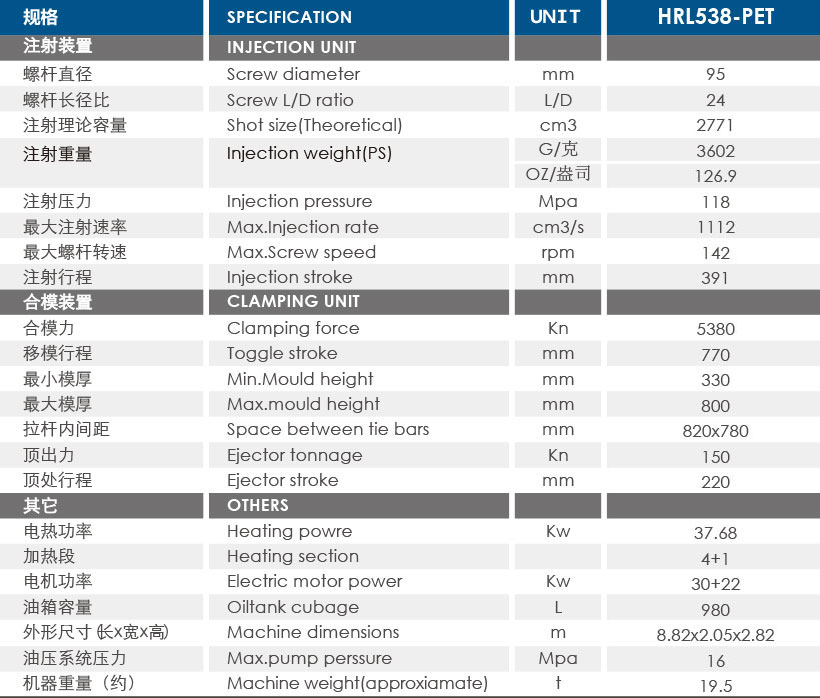

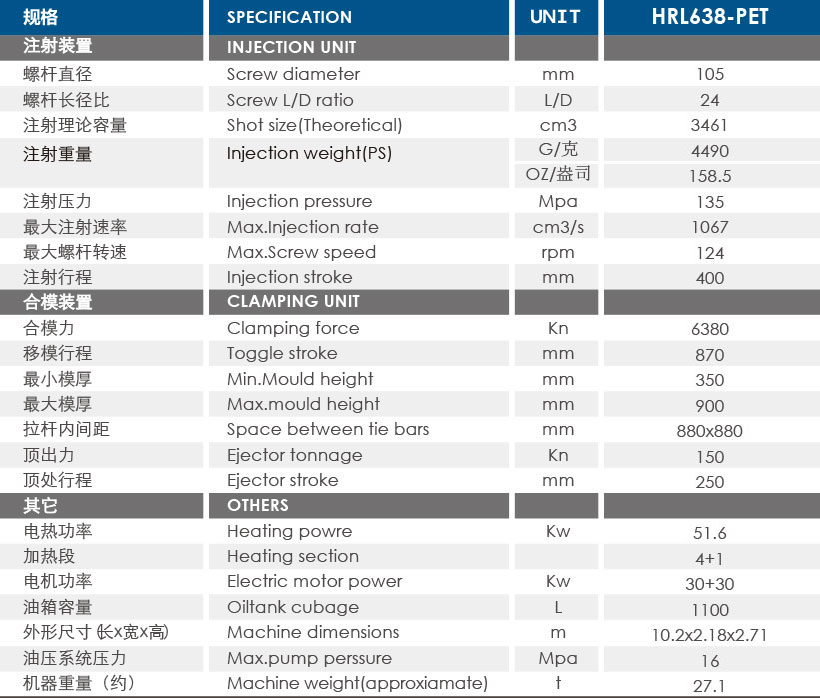

Pet Series Fast Precision Injection Moulding Machine

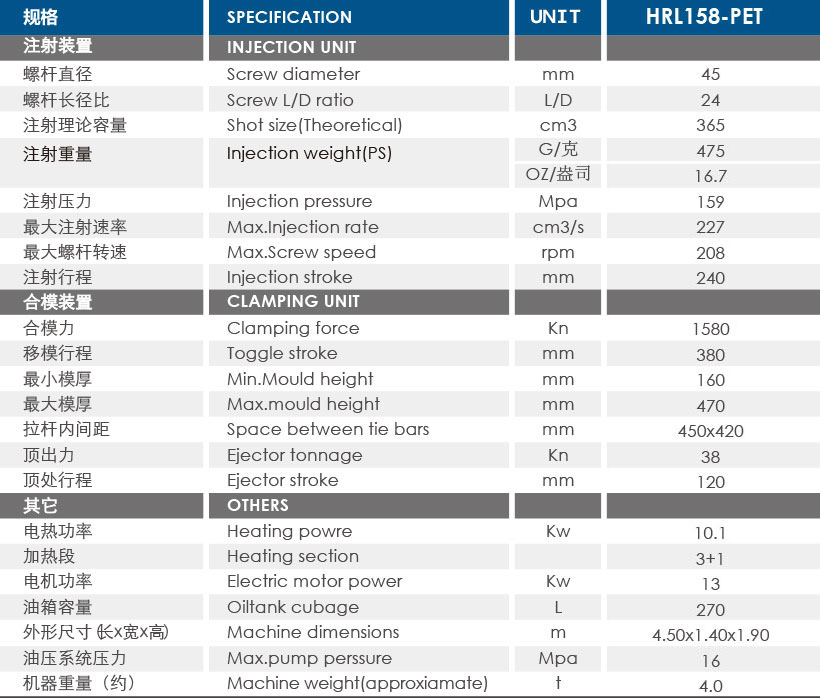

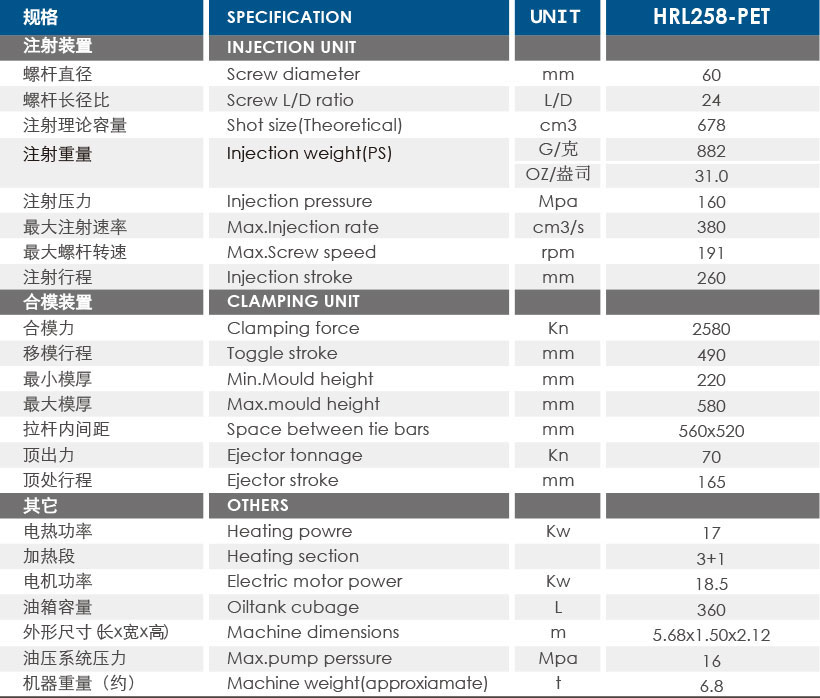

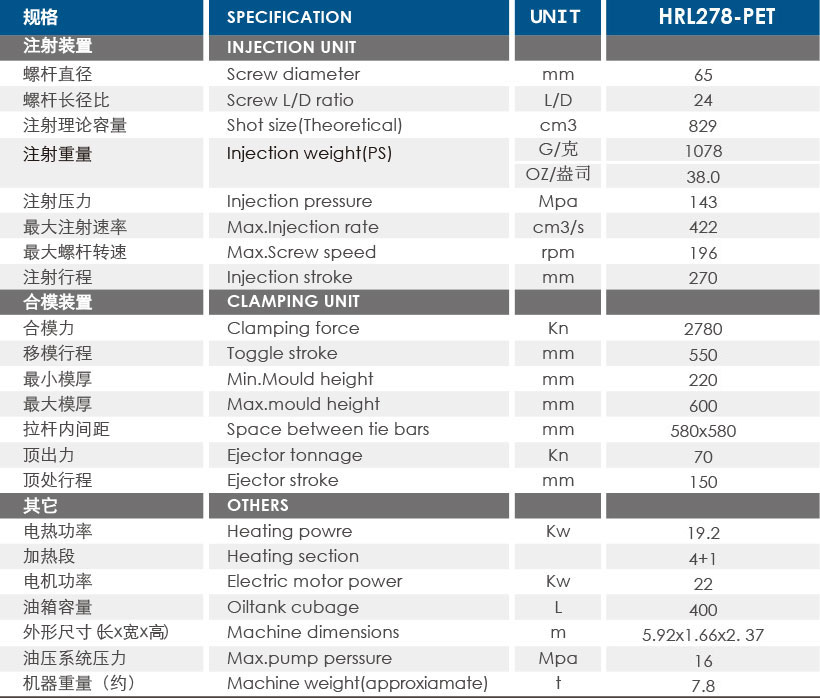

● By the recognition of the market with large column spacing, and efficient to meet the PET preform mould size is larger, the practi-cal needs of the CLAMPING force smaller industry characteristics.

● The shot weight increased by 40% compared with the conventional machine, to melt cycle is shorter.

● Increase the eject power and stroke distance are more than 30%, which is more suitable for multicavity and deep cavity forming.

● Imported high response proportional variable displacement pump hydraulic system configuration, compared with the conven-tional machine electricity saving about 20%, water saving of about 25%.

● High rigidity T type groove template structure, more convenient to replace the mold needs.